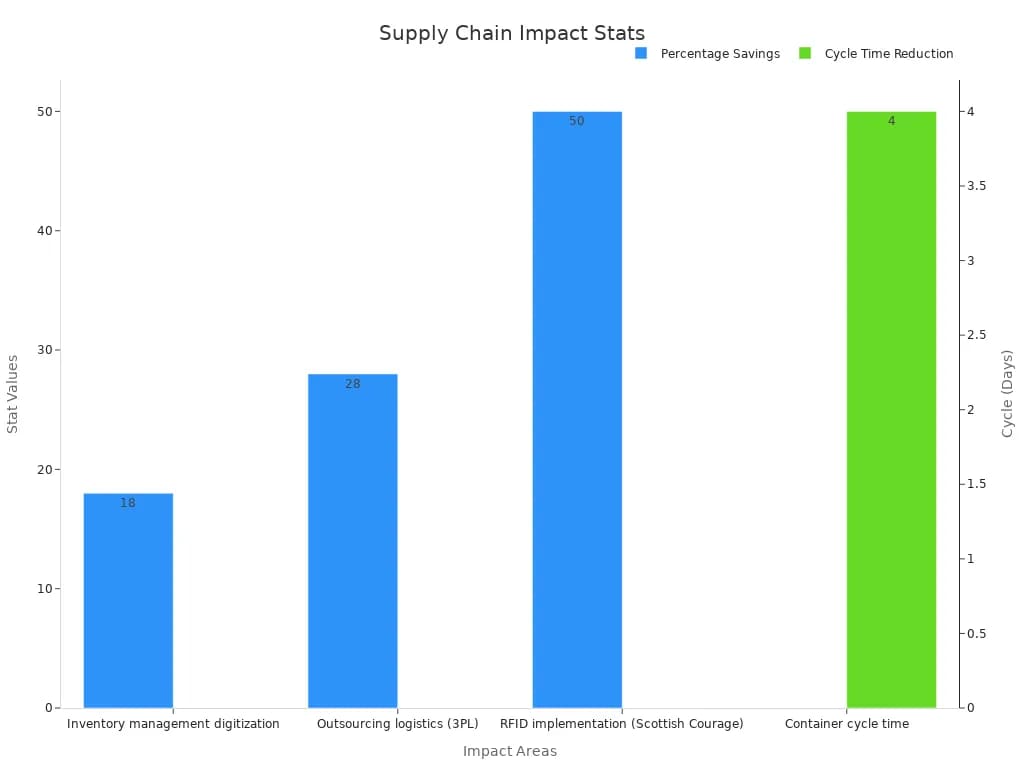

You see the logistics and supply chain management landscape changing rapidly as emerging technologies reshape the industry. Real-time data now drives decision-making, helping you achieve faster response times and improved accuracy. Companies in Malaysia that embrace supply chain digital transformation realize significant gains: for example, digitized inventory management reduces holding costs by 18%, and RFID technology can cut container cycle times by four days.

| Impact Area | Numerical Statistic | Operational Benefit/Outcome |

|---|---|---|

| Inventory management digitization | 18% reduction in holding costs | Freed working capital and reduced storage needs |

| Outsourcing logistics (3PL) | 28% cost savings | Savings on driver salaries, truck maintenance, depreciation; real-time product movement visibility |

| RFID implementation (Scottish Courage) | 50% reduction in keg losses | Reduced inventory losses and improved asset tracking |

| RFID implementation (Scottish Courage) | 4-day reduction in container cycle time | Faster container turnaround, reduced inventory levels |

You benefit from supply chain technology such as AI, IoT, and advanced analytics, which enhance logistics technology and supply chain management. AI adoption in supply chains has grown by 270% in three years, resulting in up to 35% better inventory levels and 65% higher service levels. These advancements in logistics technology and supply chain management give you a competitive edge, improve efficiency, and enable smarter, data-driven operations.

Artificial intelligence is transforming how you manage logistics and supply chain technology. You now have access to tools that optimize operations, improve demand forecasting, and drive process automation. With artificial intelligence, you can analyze vast amounts of data in real time, uncover patterns, and make smarter decisions faster.

Predictive analytics powered by artificial intelligence gives you a competitive edge. You can combine historical sales data with real-time market trends to forecast demand more accurately than ever before. This approach helps you reduce stockouts, avoid overstock, and align resources with actual needs. Companies like Walmart, Siemens, FedEx, and DHL use predictive analytics to optimize inventory, production, and logistics automation. The table below highlights how different industries benefit from these technologies:

| Industry | Company | AI Application | Impact on Operations |

|---|---|---|---|

| Retail | Walmart | AI-powered inventory management | Optimizes stock placement, reduces shortages, improves customer availability |

| Manufacturing | Siemens | AI-driven production planning | Anticipates material needs, reduces downtime, enhances workflow efficiency |

| Logistics | FedEx | AI-based logistics optimization | Forecasts demand surges, enables proactive staffing and warehouse optimization |

| Logistics | DHL | AI-enhanced supply chain efficiency | Predicts package volume, enables dynamic route planning, reduces delays and fuel consumption |

Predictive analytics adapts to new data, continuously improving forecast accuracy and helping you respond quickly to market changes.

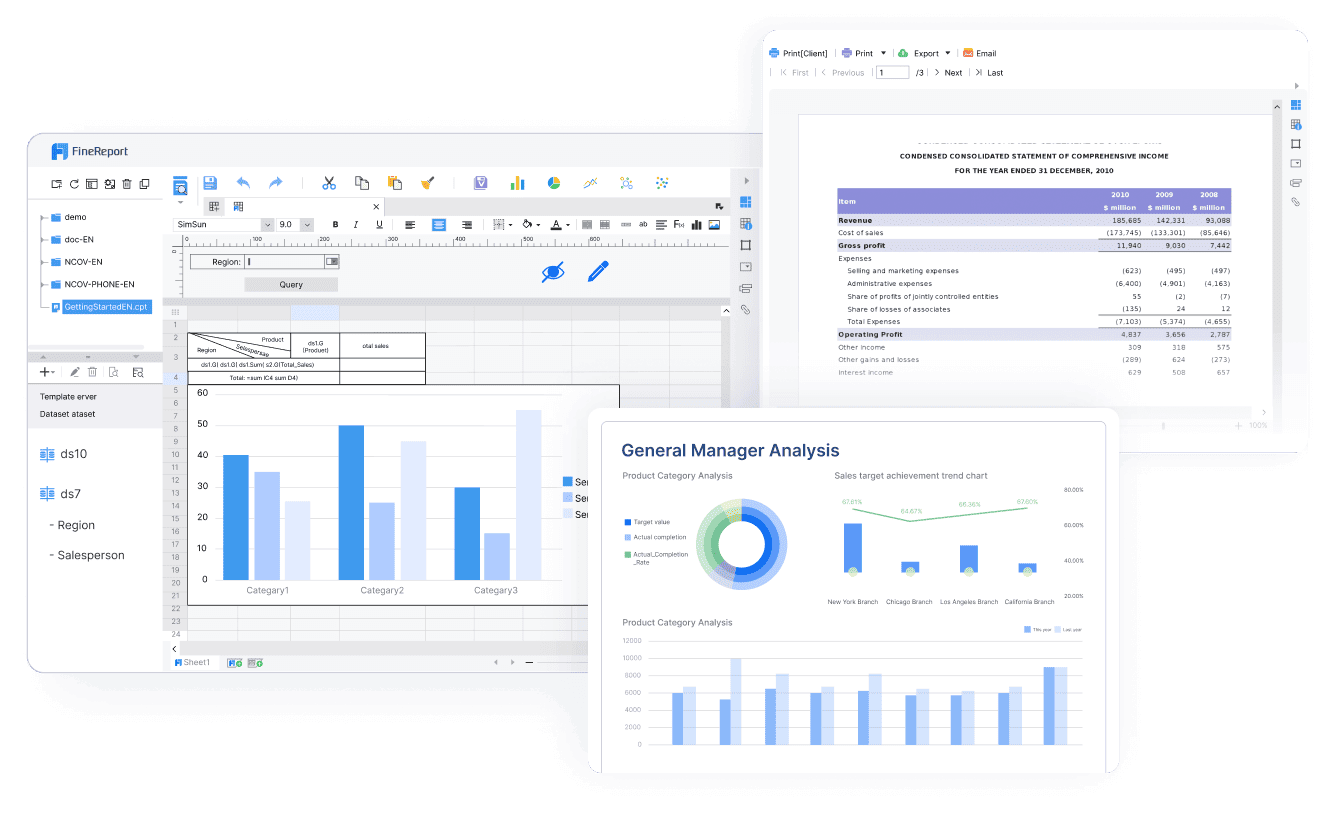

Automation, driven by artificial intelligence, streamlines your supply chain technology. You can automate repetitive tasks, monitor shipments, and manage inventory with minimal manual intervention. Robotics and automation increase speed and accuracy in warehouses, while predictive analytics identifies bottlenecks before they disrupt operations. Artificial intelligence also strengthens risk management and supports sustainability by reducing resource waste. With solutions like FanRuan and FineReport, you gain AI-driven analytics that empower you to visualize data, automate reporting, and optimize logistics automation. These tools help you build a resilient, efficient, and future-ready supply chain.

Big data has become a game changer for supply chain optimization and logistics optimization. You now have access to massive amounts of information from sensors, transactions, and partner systems. This data helps you make smarter decisions, improve efficiency, and reduce costs. Studies show that big data analytics boost supply chain visibility, coordination, and demand forecasting accuracy. For example, UPS uses data-driven route optimization to save 1.6 million gallons of gasoline each year. These results prove that data analytics can drive real improvements in your operations.

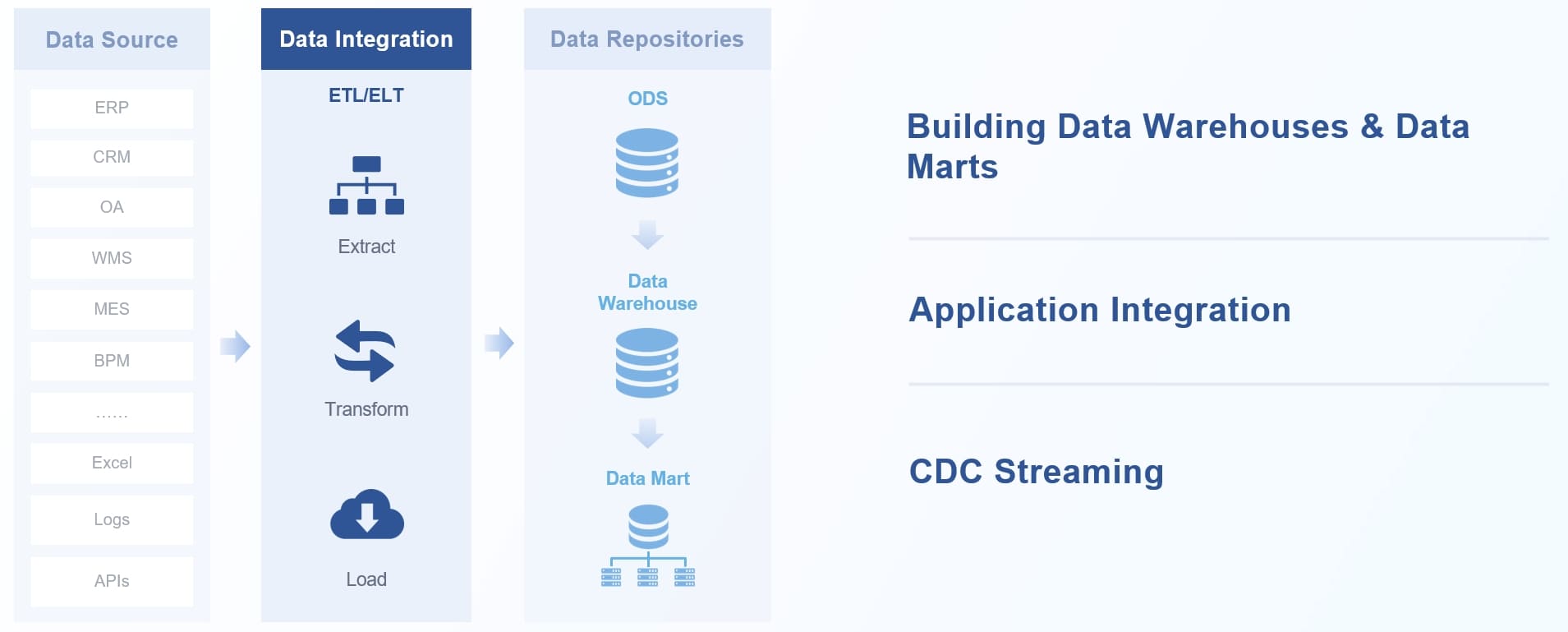

You often face the challenge of bringing together data from many sources—ERP, WMS, TMS, and POS systems. When you integrate this information, you gain a complete view of your supply chain. Industry research shows that 97% of companies invest in big data projects, but only 24% feel fully data-driven. This gap highlights the need for strong data integration tools. FineReport and FanRuan help you break down data silos. With FineDataLink, you can connect over 100 data sources and synchronize information in real time. This integration supports accurate reporting and enables you to respond quickly to changes in demand or supply.

You can use advanced data analytics and predictive analytics to optimize every part of your supply chain. Platforms like FineReport let you build dashboards that track inventory, supplier performance, and delivery timelines. These dashboards give you real-time insights, so you can spot risks and act fast. For example, dashboards can monitor order fulfillment rates, supplier quality, and transportation costs. By automating data collection and visualization, you reduce manual errors and save time. This approach supports logistics optimization and helps you achieve better customer satisfaction. When you use integrated analytics, you make your supply chain more agile and competitive.

Cloud computing solutions have become essential in logistics and supply chain management. You now have the power to scale operations quickly and collaborate with partners worldwide. Cloud platforms give you real-time access to data, which helps you make faster and smarter decisions. Many leading companies in Malaysia rely on cloud computing solutions to improve efficiency, reduce costs, and overcome cybersecurity challenges.

You can expand your logistics network without heavy investments in hardware. Cloud computing solutions let you adjust resources as your business in Malaysia grows or as demand changes. For example, companies like FedEx and Walmart use cloud platforms to monitor shipments and manage inventory at scale. The table below highlights how organizations leverage cloud computing solutions for scalability and efficiency:

| Use Case / Company | Description | Outcome / Benefit |

|---|---|---|

| FedEx | Uses Microsoft Azure cloud for real-time risk monitoring of packages along delivery routes | Improved risk tracking by monitoring weather and delays |

| Walmart | Employs SellerCloud, a cloud-based platform for inventory management | Maintains ideal inventory levels with timely alerts |

| Deutsche Bahn | Uses KONUX smart sensors and cloud solutions to monitor equipment and infrastructure | Reduced downtime and costs by 25% through predictive maintenance |

| Acropolium Transportation Management | Modernized TMS system, migrated to AWS hosting | Saved $5,000/month on database, $10,000/year on hosting, expanded customer base to billion shippers |

You benefit from the ability to scale up or down instantly. This flexibility helps you respond to market shifts and seasonal peaks. However, you must also address cybersecurity challenges as your data footprint expands.

Cloud computing solutions foster collaboration by allowing you and your partners to share data in real time. You can coordinate shipments, track inventory, and communicate with suppliers from anywhere. Real-time data sharing increases transparency and builds trust across your supply chain. For instance, Everstream Analytics uses a cloud-based risk forecasting platform to help companies in Malaysia reduce income loss by 30% during disruptions.

FineReport supports your collaborative efforts with robust cloud integration. You can connect to cloud data warehouses, synchronize data instantly, and create dashboards accessible to your entire team in Malaysia. As more businesses in Malaysia adopt cloud computing solutions, you see rapid growth in the cloud market. This trend drives demand for secure, scalable, and cost-effective platforms. FineReport’s integration with cloud data warehouses enables you to manage large datasets, improve business intelligence, and address cybersecurity challenges with advanced security controls in Malaysia.

Tip: When you move operations to the cloud, always review your cybersecurity challenges. Protect sensitive data and ensure compliance with industry standards in Malaysia.

Autonomous vehicles and drones are changing how you approach logistics automation. These technologies help you move goods faster, safer, and with fewer errors. You can now rely on robotics and automation to handle tasks that once required manual labor. This shift allows you to focus on higher-value activities and improve your supply chain’s efficiency.

You see delivery automation making a big impact in last-mile logistics. Drones deliver packages to remote areas, bypassing traffic and reducing delivery times. Autonomous trucks transport goods across long distances, operating around the clock. You can use collaborative robots to load and unload cargo, speeding up warehouse operations. These robots work alongside your team in Malaysia, boosting productivity and reducing workplace injuries. Companies like Amazon and UPS use drones and autonomous vehicles to streamline deliveries and cut costs. By adopting automation, you can meet customer demands for faster shipping and improve your bottom line.

Note: Delivery automation also supports sustainability. Electric drones and vehicles produce fewer emissions, helping you reach your environmental goals.

You gain real-time visibility into your fleet by using advanced tracking shipments technology. Sensors and GPS devices monitor vehicle locations, fuel usage, and delivery status. This data helps you optimize routes, reduce delays, and respond quickly to issues. Collaborative robots can assist with loading and unloading, ensuring that shipments move smoothly through your network. Robotics and automation also play a role in maintaining vehicles, as automated systems schedule maintenance and alert you to potential problems. With accurate tracking shipments, you can provide customers with up-to-date delivery information and build trust in your service.

| Technology | Benefit | Example Use Case |

|---|---|---|

| Drones | Faster last-mile delivery | Rural package drop-offs |

| Autonomous Trucks | 24/7 long-haul transport | Cross-country freight |

| Collaborative Robots | Efficient warehouse handling | Automated loading docks |

By embracing logistics automation, you position your business in Malaysia for future growth and resilience.

You can now use digital twins to create a virtual model of your entire supply chain. A digital twin acts as a real-time digital replica of your physical assets, processes, and systems. This technology lets you visualize every step, from raw material sourcing to product delivery. You see how each part connects and interacts. You can track inventory, monitor equipment, and follow shipments—all within a single digital environment.

Tip: Digital twins help you spot weak points in your supply chain before they cause problems.

You gain a clear view of your operations. You can test changes in your virtual model before making them in the real world. For example, you might adjust warehouse layouts or reroute shipments to see how these changes affect delivery times. This approach reduces risk and saves money.

With digital twins, you can run simulations to predict how your supply chain will respond to different scenarios. You might simulate a sudden spike in demand or a supplier delay. The digital twin shows you the impact on inventory, production, and delivery. You can then make informed decisions to avoid disruptions.

Here’s how you benefit from simulation and optimization with digital twins:

| Use Case | Digital Twin Benefit |

|---|---|

| Demand Surge | Adjust inventory in advance |

| Supplier Disruption | Reroute shipments quickly |

| New Product Launch | Test logistics before rollout |

You stay ahead of challenges and keep your supply chain running smoothly. Digital twins give you the power to optimize performance, reduce costs, and deliver better results for your business in Malaysia.

Augmented reality (AR) and virtual reality (VR) are changing how you approach workforce training and warehouse automation. These technologies create immersive, interactive experiences that help your team in Malaysia learn faster and work smarter.

You can use AR and VR to train employees in realistic, risk-free environments. VR lets your team in Malaysia practice real-world tasks without danger. For example, Amazon uses VR to teach employees how to interact safely with robotics systems, which reduces accidents and improves operational efficiency. Walmart uses VR to prepare staff for high-pressure events like Black Friday, helping them build confidence and readiness. You can update VR training programs easily, so your team in Malaysia always learns the latest procedures. AR training offers hands-on simulations for tasks such as inventory management, making onboarding quicker and more effective. Studies show that AR and VR training improves learning retention and reduces training time compared to traditional methods.

You can optimize warehouse automation by integrating AR and VR into daily operations. AR smart glasses give workers visual cues and optimized routes for order picking, which speeds up the process and reduces mistakes. DHL uses AR to guide employees through warehouses, resulting in significant efficiency gains. Boeing’s use of AR in assembly tasks shows how you can reduce errors and increase productivity, benefits that transfer directly to warehouse automation. AR helps with palletizing, inventory counting, and other repetitive tasks by providing step-by-step instructions. You can also use VR for virtual tours and planning, improving understanding of warehouse layouts and workflows.

Tip: Combining AR and VR with warehouse automation helps you build a more agile, skilled, and efficient workforce.

As you look for ways to make your supply chain more responsible, green logistics and sustainability become top priorities. Companies in Malaysia now use technology to reduce waste, lower emissions, and protect the environment. You can see this shift in the growing number of research articles and global projects focused on sustainable logistics.

You have many options to support sustainability efforts in your operations. Companies in Malaysia use renewable energy, such as solar panels and wind turbines, to power warehouses and distribution centers. Electric vehicles and hybrid trucks help you cut down on fuel use and carbon emissions. Smart route planning software reduces unnecessary miles, saving both money and resources. You can also use recyclable packaging and encourage suppliers to adopt green practices. These steps not only help the planet but also improve your brand reputation.

Companies in Malaysia that invest in eco-friendly solutions often see measurable improvements in efficiency and cost savings.

You can boost energy efficiency by using advanced monitoring systems and IoT sensors. These tools track energy use in real time, helping you spot waste and make quick changes. Automated lighting, smart HVAC systems, and energy-efficient equipment lower your overall consumption. Data analytics platforms let you compare energy use across sites and set clear goals for improvement.

| Technology | Benefit |

|---|---|

| IoT Sensors | Real-time energy tracking |

| Smart HVAC Systems | Lower heating/cooling costs |

| Automated Lighting | Reduced electricity usage |

By focusing on energy efficiency, you support sustainability efforts and create a supply chain that is both cost-effective and environmentally friendly. As more companies in Malaysia adopt sustainable logistics, you help set new standards for the industry.

You need strong logistics control to stay competitive in logistics and supply chain management. FanRuan and FineReport give you the tools to monitor and manage every step of your logistics operations. You can track shipments, manage warehouse activities, and oversee transportation in real time. FineReport’s dashboards let you visualize key metrics, such as delivery times and inventory turnover. You can set up alerts for delays or bottlenecks, so you respond quickly to issues. Artificial intelligence in FineReport helps you analyze patterns and predict disruptions before they impact your business in Malaysia. You gain full visibility and control, which improves your decision-making and keeps your supply chain management agile.

Tip: Use FineReport‘s mobile dashboards to access logistics data anywhere. This flexibility helps you make fast decisions, even when you are away from your desk.

Understanding logistics volume is essential for optimizing logistics technology. FineReport enables you to analyze shipment volumes, warehouse throughput, and delivery trends with ease. You can compare historical data, spot seasonal peaks, and forecast future needs. Artificial intelligence tools in FineReport help you identify inefficiencies and recommend improvements. You can use interactive charts and tables to drill down into specific routes or products. This level of analysis supports better planning and resource allocation in supply chain management. When you leverage these insights, you reduce costs and improve service levels across your logistics and supply chain management operations.

You can rely on FanRuan and FineReport to transform your logistics technology and drive smarter supply chain management decisions.

You need a strong foundation for logistics and supply chain management. FanRuan’s FineDataLink gives you a modern data integration platform. You can connect data from over 100 sources, including ERP, WMS, and IoT devices. This platform synchronizes real-time data across your systems. You break down data silos and gain supply chain visibility. FineDataLink supports artificial intelligence by providing clean, unified data for analysis. You can automate ETL processes and share data between applications using APIs. This approach helps you manage complex supply chain networks with confidence.

You want instant insights into your operations. FineReport lets you build real-time dashboards that track every part of your supply chain management. You can monitor inventory, shipments, and supplier performance on one screen. These dashboards update automatically as new data arrives. You see trends, spot risks, and make fast decisions. Artificial intelligence and data analytics power these dashboards, giving you predictive alerts and recommendations. You improve supply chain visibility and respond quickly to changes in demand or disruptions.

Tip: Use mobile dashboards to access real-time data anywhere. Stay connected to your logistics technology and supply chain management, even when you are on the move.

You save time with FineReport’s ready-made templates. These templates cover common supply chain management scenarios, such as inventory control, procurement analysis, and logistics performance. You can customize templates to fit your business needs in Malaysia. Each template uses real-time data and advanced data analytics to deliver actionable insights. You benefit from artificial intelligence features that highlight trends and suggest improvements. With these templates, you standardize reporting and boost supply chain visibility across your organization.

| Template Type | Use Case | Benefit |

|---|---|---|

| Inventory Dashboard | Inventory control | Real-time tracking, fewer errors |

| Supplier Analysis | Procurement optimization | Better supplier management |

| Logistics Report | Delivery performance | Improved logistics technology |

You empower your team in Malaysia to make smarter decisions and drive efficiency in logistics and supply chain management.

Emerging technologies continue to reshape logistics and supply chain management. You see robotics, AI, and IoT driving efficiency and real-time insights. Nearly 80% of professionals plan to invest in automation by 2025. Big data analytics and blockchain offer transparency and smarter decision-making. Sustainability trends push you toward greener operations as consumer demand rises. Explore solutions like FanRuan and FineReport to future-proof your supply chain. Stay ahead by adopting digital tools that optimize performance and support your growth.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What Is Supply Chain Analytics

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is a data management platform in 2025

A data management platform in 2025 centralizes, organizes, and activates business data, enabling smarter decisions and real-time insights across industries.

Howard

Dec 22, 2025

Top 10 Database Management Tools for 2025

See the top 10 database management tools for 2025, comparing features, security, and scalability to help you choose the right solution for your business.

Howard

Dec 17, 2025

Best Data Lake Vendors For Enterprise Needs

Compare top data lake vendors for enterprise needs. See which platforms offer the best scalability, integration, and security for your business.

Howard

Dec 07, 2025