You encounter six main types of supply chain models: Continuous Flow, Fast Chain, Efficient Chain, Agile, Custom-Configured, and Flexible. Choosing the right supply chain model boosts efficiency and strengthens your ability to handle disruptions. Recent research shows that aligning your supply chain management with business strategy helps you minimize costs and maximize customer service. Digital tools such as FineReport make it easier to visualize data, analyze trends, and support smarter decisions across your supply chain.

You will find that the types of supply chain models play a key role in shaping how businesses operate. Each model addresses different needs and challenges. The six main types of supply chain are Continuous Flow, Fast Chain, Efficient Chain, Agile, Custom-Configured, and Flexible. These models fall into two main orientations: efficiency and responsiveness. You can see the differences in the table below:

| Supply Chain Model | Orientation | Key Features |

|---|---|---|

| Continuous Flow | Efficiency | Steady stream of products, best for stable demand |

| Fast Chain | Responsiveness | Speed and flexibility for changing customer needs |

| Efficient Chain | Efficiency | Focus on cost reduction and operational efficiency |

| Agile Chain | Responsiveness | Combines efficiency with quick response to market changes |

| Custom-Configured | Responsiveness | Tailored to specific customer requirements |

| Flexible Chain | Efficiency | Balances efficiency with adaptability to demand shifts |

You can match each type of supply chain to different industries. For example, the fast chain model works well in the fashion industry, where trends change quickly. The efficient chain model fits businesses that rely on accurate forecasts. The agile model supports specialty item producers, while the custom-configured model serves companies needing product customization. Flexible models help businesses with seasonal demand.

Understanding the types of supply chain models helps you make better decisions for your business. When you choose the right supply chain model, you improve efficiency, reduce costs, and respond faster to market changes. Studies show that sustainable supply chain management increases competitiveness and market share. Companies that invest in the right supply chain model often see better financial performance and stronger customer loyalty.

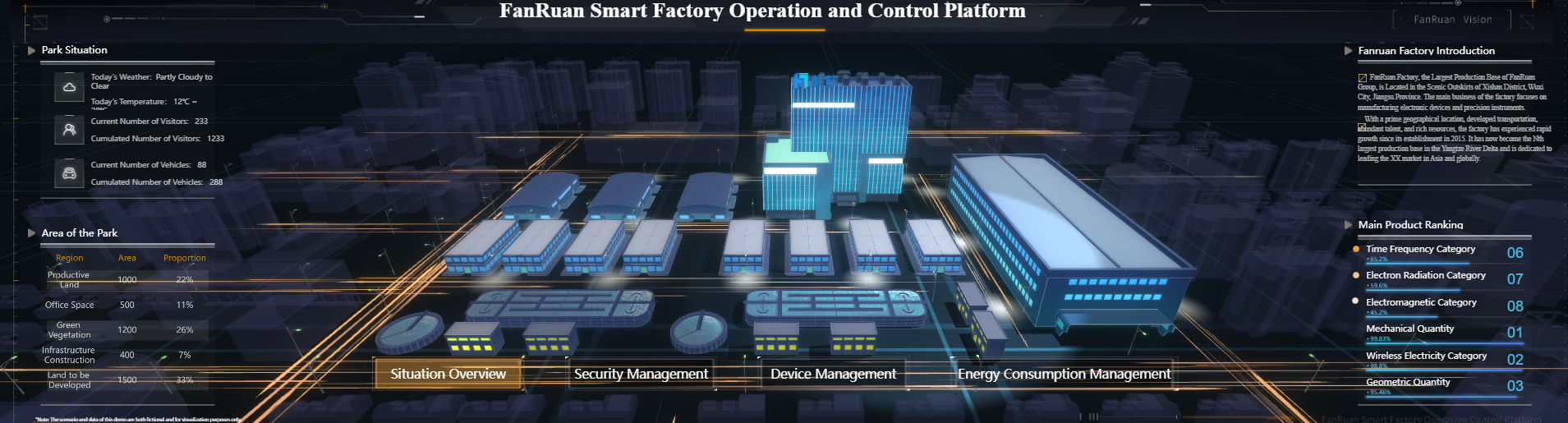

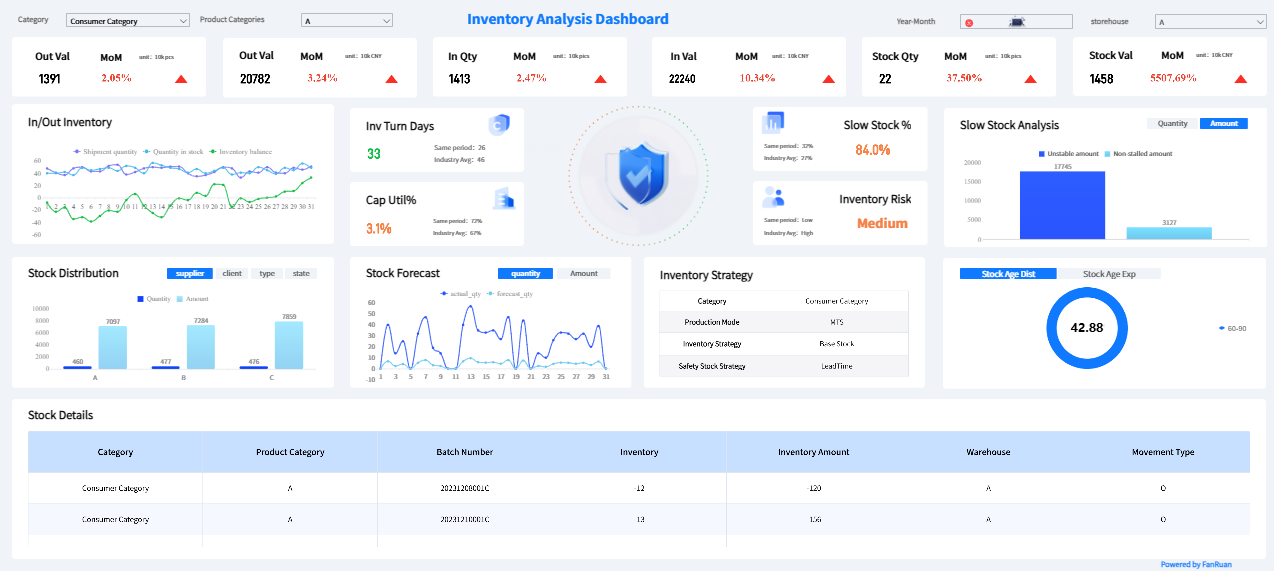

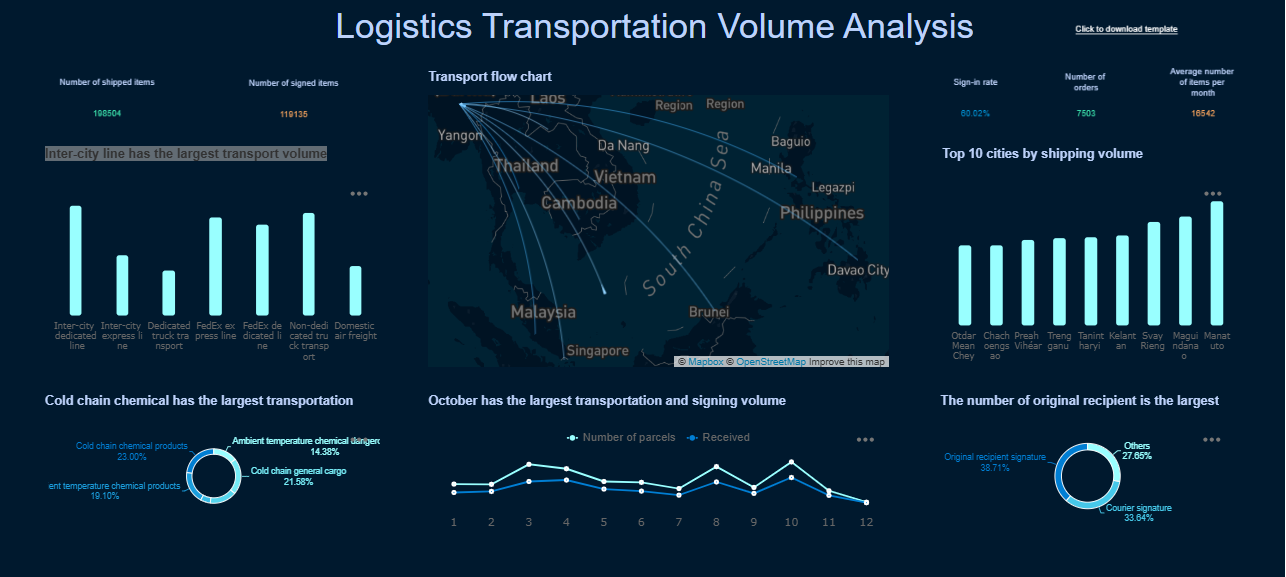

You can use digital tools like FineReport to visualize and analyze data from different supply chain models. FineReport offers features such as trajectory maps for logistics tracking, Sankey diagrams for data flow analysis, and bullet maps for monitoring trends. These tools help you gain insights and make informed decisions, no matter which types of supply chain you use.

You will find that the continuous-flow model stands out for its high level of standardization and efficiency. This supply chain model works best when you produce the same product over long periods with little variation in demand. You often see long production runs and a strong focus on lean manufacturing. Companies using the continuous flow model rely on Just-In-Time (JIT) delivery to minimize inventory and reduce waste.

Here are some key actions and their expected outcomes in a continuous-flow model:

| Key Actions | Expected Outcomes |

|---|---|

| Analyze flow, collect data | Bottleneck visibility |

| Reduce downtime, optimize scheduling | Increased throughput |

| Invest in capacity, technology | Constraint elimination |

You can expect low demand variability and a steady stream of products moving through the supply chain. For example, P&G’s Synchronized Beauty Production reduced process times from 2.5 days to just 10 minutes by using digital integration. This demonstrates how the continuous-flow model can drive dramatic improvements in efficiency.

Tip: Focus on standardization and process optimization to maximize the benefits of the continuous-flow model.

You will see the continuous flow model most often in industries where demand remains stable and products do not change frequently. The automotive, food and beverage, and consumer goods sectors have successfully implemented this supply chain model. Companies like Toyota, Boeing, Harley-Davidson, and Nestlé have reported measurable benefits:

| Manufacturing Sector | Measurable Benefits |

|---|---|

| Boeing | Assembly time cut from 28 to 11 days; defect rates down 65% |

| Toyota | Vehicle completion every 55 seconds; quality above 99% |

| Harley-Davidson | Production time cut by 60%; inventory costs down 75% |

| Nestlé | Production efficiency up 35%; water usage down 40% |

You can use FineReport to support your continuous-flow model by tracking real-time production data, visualizing bottlenecks, and optimizing scheduling. FineReport’s dashboards and data entry forms help you monitor key metrics and streamline your processes, making it easier to achieve continuous improvement.

You will find the fast model supply chain model is designed for speed and adaptability. This approach focuses on minimizing lead times and accelerating product flow through your operations. You can respond quickly to changes in customer demand, which is essential in industries where trends shift rapidly. The fast model prioritizes speed and flexibility over cost reduction. You rely on real-time data to make decisions and adjust your supply chain model as needed.

The table below highlights the main features of the fast model supply chain model:

| Feature | Description |

|---|---|

| Minimized Lead Times | You reduce the time from order to delivery. |

| Accelerated Product Flow | You move products quickly through your operations. |

| Rapid Response to Demand Changes | You adapt to customer needs without delay. |

| Prioritization of Speed & Flexibility | You focus on quickness and adaptability. |

| Use of Real-Time Data | You use current information for decision-making. |

| Agile Suppliers | You work with suppliers who can respond fast. |

| Responsive Logistics | Your logistics systems react quickly to disruptions. |

| AI-Driven Demand Forecasting | You use artificial intelligence to predict customer needs. |

| Real-Time Inventory Tracking | You monitor inventory using IoT technology. |

| Cloud-Based Collaboration | You share information and coordinate using cloud platforms. |

| Automated Warehouses | You use automation to improve storage and retrieval. |

| Visibility | You track inventory and shipments for transparency. |

| Agility and Multiple Sourcing | You plan for risks with flexible sourcing strategies. |

| Continuous Monitoring | You assess and adjust your operations using predictive analytics. |

Tip: You should invest in technology that supports real-time monitoring and automation. This will help you maintain the speed and flexibility required by the fast model.

You will see the fast model supply chain model used most often in industries where product life cycles are short and market trends change quickly. Fashion and sportswear companies, such as Adidas, rely on the fast model to launch new products and respond to consumer preferences. You can benefit from this model if you need to minimize lead times and bring products to market quickly.

The table below shows how the fast model supports operations in the fashion industry:

| Aspect | Description |

|---|---|

| Industry | Fashion and sportswear, with Adidas as a leading example. |

| Rapid Market Response | You react quickly to consumer needs and market trends. |

| Lower Lead Times | You shorten the time from design to retail, improving customer satisfaction. |

| In-House Production Control | You plan to bring more production in-house for better quality and agility. |

| Increased Operational Costs | You may face higher expenses due to the focus on speed. |

| Overproduction Risk | You risk excess inventory if demand is misjudged. |

| Quality Assurance Issues | You must monitor quality closely during fast production cycles. |

| Complex Supply Chain Management | You need careful management of reactive and interdependent operations. |

You can use FineReport to support your fast model supply chain model by enabling real-time data visualization and collaboration. FineReport helps you track inventory, monitor logistics, and analyze demand trends, making your operations more responsive and efficient. When you understand the six supply chain model types, you can choose the fast model to gain a competitive edge in dynamic markets.

You will find that the efficient model stands out when you want to maximize cost savings and streamline your operations. This efficiency-focused supply chain works best in environments with stable demand and predictable product flows. You rely on accurate forecasting, strong supplier relationships, and tight process control. The efficient chain model helps you minimize waste and reduce unnecessary expenses.

You can measure the performance of the efficient model using several key operational metrics. The table below highlights the most important ones:

| Metric | Description |

|---|---|

| Cost Reduction | Focus on minimizing costs while ensuring timely order fulfillment. |

| Inventory Management | Balancing stock levels to meet demand without excess capital tied up. |

| Lead Time Optimization | Reducing the time from order placement to delivery completion. |

| Vendor Selection Criteria | Evaluating suppliers based on reliability, defect rates, and compliance with specifications. |

| Order Cycle Time | Duration between order placement and delivery completion. |

| On-time Delivery Rates | Percentage of shipments arriving within scheduled timeframes. |

| Perfect Order Fulfillment | Measures orders delivered complete, accurate, on time, and damage-free. |

| Warehouse Utilization Rates | Indicates storage space efficiency, highlighting potential bottlenecks in the supply chain. |

You should focus on these metrics to ensure your efficiency-focused supply chain delivers consistent results. The efficient model depends on continuous improvement and process optimization.

Note: You can achieve the best results with the efficient chain model when you have reliable demand forecasts and established supplier networks.

You will see the efficient model used in industries where cost control and operational consistency are critical. Companies that produce high-volume, low-variation products benefit the most from this supply chain model. The efficient model supports businesses that want to reduce inventory costs, improve delivery reliability, and maintain lean operations.

Here are some real-world examples of companies that have improved their efficiency-focused supply chain by adopting the efficient model:

You can use the efficient chain model to drive cost savings and operational excellence. FineReport supports your efficiency-focused supply chain by providing real-time dashboards, inventory tracking, and supplier performance analysis. These tools help you monitor key metrics and make data-driven decisions for continuous improvement.

You will find the agile model stands out for its ability to help you respond quickly to market changes. This supply chain model focuses on flexibility and resiliency, allowing you to adapt to sudden shifts in demand or supply. You can recover from disruptions and manage risks more effectively. The agile supply chain model supports rapid decision-making and encourages collaboration across your organization.

Tip: You should invest in digital tools and data analytics to maximize the benefits of the agile supply chain. Real-time information helps you make faster decisions and stay ahead of competitors.

You will see the agile model used in industries where demand is unpredictable and product life cycles are short. Companies that need to launch new products quickly or respond to fashion trends benefit from this approach. The agile supply chain model works well for businesses that want to minimize overproduction and reduce excess inventory.

| Industry | Company | Agile Supply Chain Implementation Description |

|---|---|---|

| Fashion | Zara | Utilizes a hybrid approach, applying lean principles to stable products and agile methods to trend-driven items. |

| Consumer Goods | Kimberly-Clark | Employs lean methods for standardized products and agile practices for new product launches and demand spikes. |

| Fashion | H&M | Designs and produces based on real-time demand to minimize overproduction and excess inventory. |

| Footwear | Nike | Adapts quickly to customer needs, especially with customizable products like Nike Flyknit shoes. |

You can use the agile model to improve responsiveness and flexibility in your supply chain. FineReport supports the agile supply chain by providing real-time dashboards, data entry forms, and advanced analytics. These tools help you track demand, monitor inventory, and adjust your operations quickly. When you understand the six supply chain model types, you can choose the agile supply chain model to stay competitive in fast-moving markets.

You will see that the custom-configured supply chain model stands out in "Understanding the Six Supply Chain Model Types" because it adapts to the unique requirements of each product and company. This model emphasizes product-specific analysis, which means you evaluate and improve your supply chain based on the needs of individual products. You use a target system to measure supply chain performance, allowing you to analyze different improvement options in a systematic way. The custom-configured model is highly adaptable. You can respond effectively to both stable and volatile demand situations. This flexibility makes your supply chain robust when you plan for uncertainties.

Note: When you use the custom-configured supply chain model, you gain the ability to tailor your processes for each product. This approach helps you optimize performance and manage risks more effectively.

You will find the custom-configured supply chain model most useful when your business needs to meet specific customer requirements or handle a diverse product portfolio. Companies that offer customization or modular products benefit from this model. You can see how leading businesses apply this strategy in "Understanding the Six Supply Chain Model Types" by looking at the table below:

| Company | Custom-Configured Supply Chain Strategy |

|---|---|

| Tesla | Online customization integrated with manufacturing, utilizing modular processes and real-time data analytics. |

| Apple | Real-time demand forecasting and modular designs for quick market adaptation. |

You should consider the custom-configured model if you operate in industries such as automotive, electronics, or consumer goods, where customer preferences change rapidly. This model allows you to deliver personalized products while maintaining efficiency. You can also use advanced analytics and modular design to streamline your operations. By understanding the six supply chain model types, you can decide if the custom-configured approach fits your business goals and helps you stay competitive in a changing market.

When you explore the Flexible Supply Chain Model in the context of Understanding the Six Supply Chain Model Types, you discover a system built for rapid adaptation. This model gives you the ability to adjust quickly when demand or market conditions shift. You can scale your operations up or down as needed, which helps you stay competitive during both slow and busy periods. Flexibility also means you can balance operational costs while still responding quickly to changes.

You will notice that leading companies such as Unilever and Procter & Gamble use this model to manage demand fluctuations, especially during unpredictable events like the COVID-19 pandemic. The table below summarizes the main features that define the flexible supply chain model:

| Feature | Description |

|---|---|

| Adaptability | You can quickly adjust to changes in demand and market conditions. |

| Scalability | You have the capacity to expand or contract operations based on market needs. |

| Cost-Responsiveness | You balance operational costs while ensuring a quick response to market changes. |

| Industry Example | Unilever and Procter & Gamble use this model to manage demand during crises and disruptions. |

Note: The flexible supply chain model helps you maintain service levels and control costs, even when the market becomes unpredictable.

You will find the flexible supply chain model most effective when your business faces frequent demand swings or seasonal peaks. This approach works well if you need to position inventory closer to customers, maintain safety stock, or optimize your distribution network during high-volume periods. The flexible model supports strategies such as forward deploying inventory, building resilient safety stock, and enhancing distribution networks.

Here is a table that highlights practical use cases and their benefits within the flexible supply chain model:

| Use Case | Description | Benefits |

|---|---|---|

| Forward Deploying Inventory | You position inventory near demand hotspots to reduce transit time. | Faster fulfillment, lower transportation costs |

| Building Resilient Safety Stock | You maintain optimal safety stock to buffer against fluctuations. | Protection against uncertainty, seasonal readiness |

| Optimizing Distribution | You enhance distribution networks during high volume periods. | Surge capacity, better 3PL relationships, efficiency |

When you apply the flexible supply chain model as part of Understanding the Six Supply Chain Model Types, you gain the ability to respond to market changes without sacrificing efficiency. This model is especially valuable for businesses in consumer goods, retail, and industries where demand can change quickly.

When you start choosing the right supply chain model, you need to evaluate several important factors. Each business faces unique challenges, so you must match your supply chain strategy to your company's goals and market conditions. You should look at your industry characteristics, company size, product life cycle, demand variability, customer expectations, and geographical distribution. These elements help you decide which supply chain models fit your needs.

| Factor | Description |

|---|---|

| Industry Characteristics | The nature of your industry shapes your supply chain model. Product types, demand patterns, and competition all play a role. |

| Company Size | Larger companies have more resources and infrastructure. Smaller firms may need simpler models. |

| Product Life Cycle | Products with stable demand work well with efficient models. High variability calls for agile approaches. |

| Demand Variability | You must understand how demand changes over time. This helps you select the right model. |

| Customer Expectations | Lead times, customization, and service levels matter when you choose your supply chain strategy. |

| Geographical Distribution | The location of suppliers and customers affects your supply chain management decisions. |

You should also consider the challenges that come with transitioning between supply chain models. Restructuring often requires contingency plans and extra inventory. Communication issues can slow down operations, so you need open channels with partners and internal teams. Complex demand forecasting demands advanced technology. Port congestion and supply chain fragmentation require diverse suppliers and better collaboration. Digital transformation needs intelligent infrastructure, and labor pressures call for flexible contracts.

Change management is crucial in ensuring agility and readiness in the face of these challenges. For example, Crowley and DSV, two prominent companies in the logistics and transportation sector, have demonstrated the effectiveness of change management in improving business outcomes.

Crowley and DSV have shown that effective change management leads to improved results in logistics and transportation. You can learn from their experience and apply similar strategies in your own supply chain management.

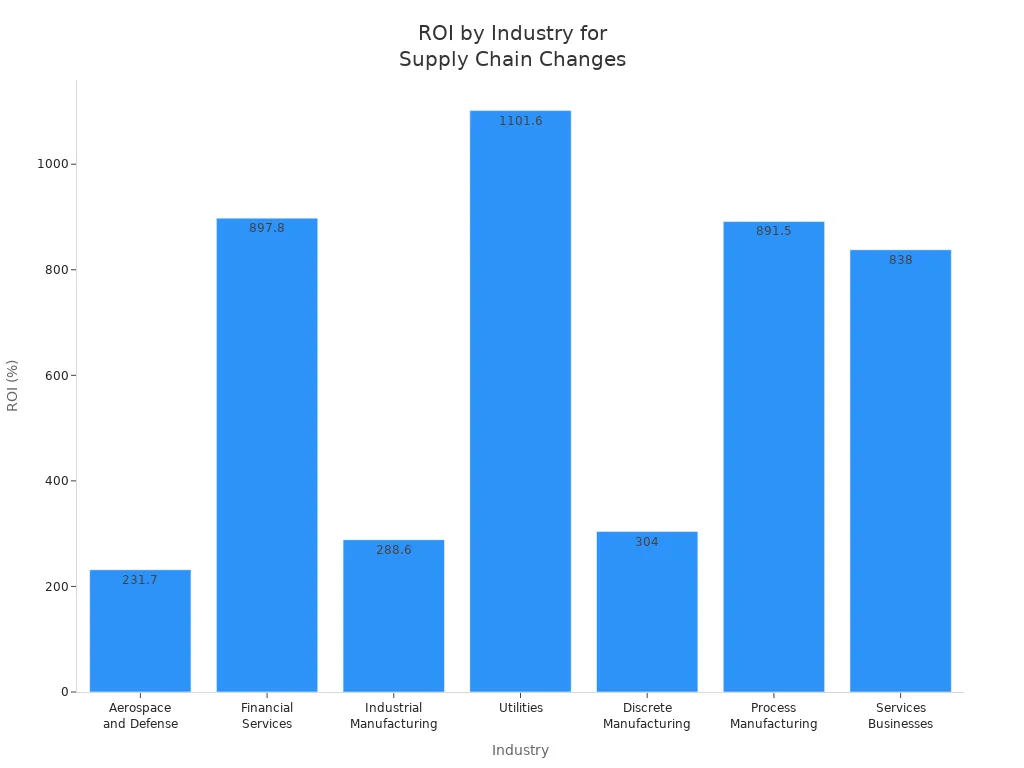

When you measure the return on investment (ROI) for supply chain model changes, you should look beyond cost reduction. Time saved and operational efficiency matter just as much. Leading companies in aerospace, manufacturing, and utilities report significant ROI when they focus on both reduction and avoidance.

| Industry | ROI (Reduction and Avoidance) | ROI (Only Cost Reduction) |

|---|---|---|

| Aerospace and Defense | 231.7% | N/A |

| Financial Services | 897.8% | N/A |

| Industrial Manufacturing | 288.6% | 246.8% |

| Utilities | 1,101.6% | 642.9% |

| Discrete Manufacturing | 304% | 509.9% |

| Process Manufacturing | 891.5% | N/A |

| Services Businesses | 838% | N/A |

A furniture retailer reduced its customs compliance error rate from 7% to 0.5% by centralizing supply chain data. This led to fewer fines and better compliance. The same retailer used technology to manage disruptions, redirecting products quickly and minimizing financial impacts.

You should also pay attention to the latest trends in supply chain model innovation. AI and machine learning improve decision-making and efficiency. Blockchain provides secure and transparent records. IoT transforms visibility and monitoring. Digital supply networks give you real-time data for better decisions. Companies like Unilever and Walmart use digital transformation to optimize inventory and reduce emissions.

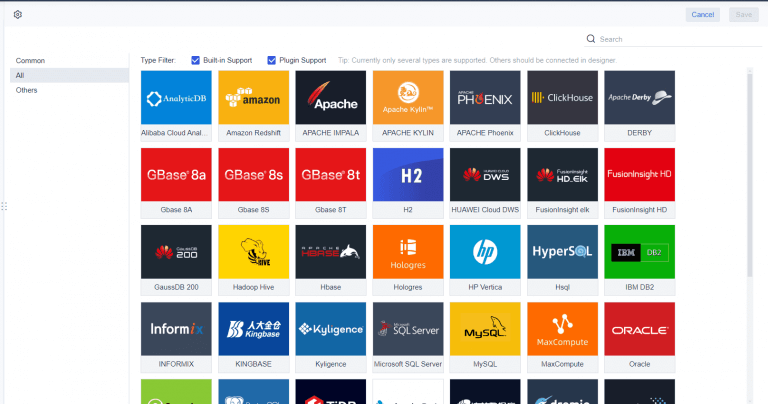

FineReport helps you make smarter choices when you select supply chain models. You can integrate data from procurement, inventory, and sales systems. FineReport connects with ERP, MES, and SRM platforms, giving you real-time insights on a unified dashboard. You can use low-code functionality to simplify data integration and eliminate silos. FineReport consolidates information from multiple sources, making it easy for you to interact, explore, and analyze data.

| Feature | Description |

|---|---|

| Data Integration | FineReport brings together data from ERP, MES, and SRM systems. You get real-time reporting and insights on one platform. |

| Low-Code Functionality | You can integrate data easily, removing barriers between departments and systems. |

| Data Visualization | FineReport creates dashboards that show information from different sources. You can analyze and explore data quickly. |

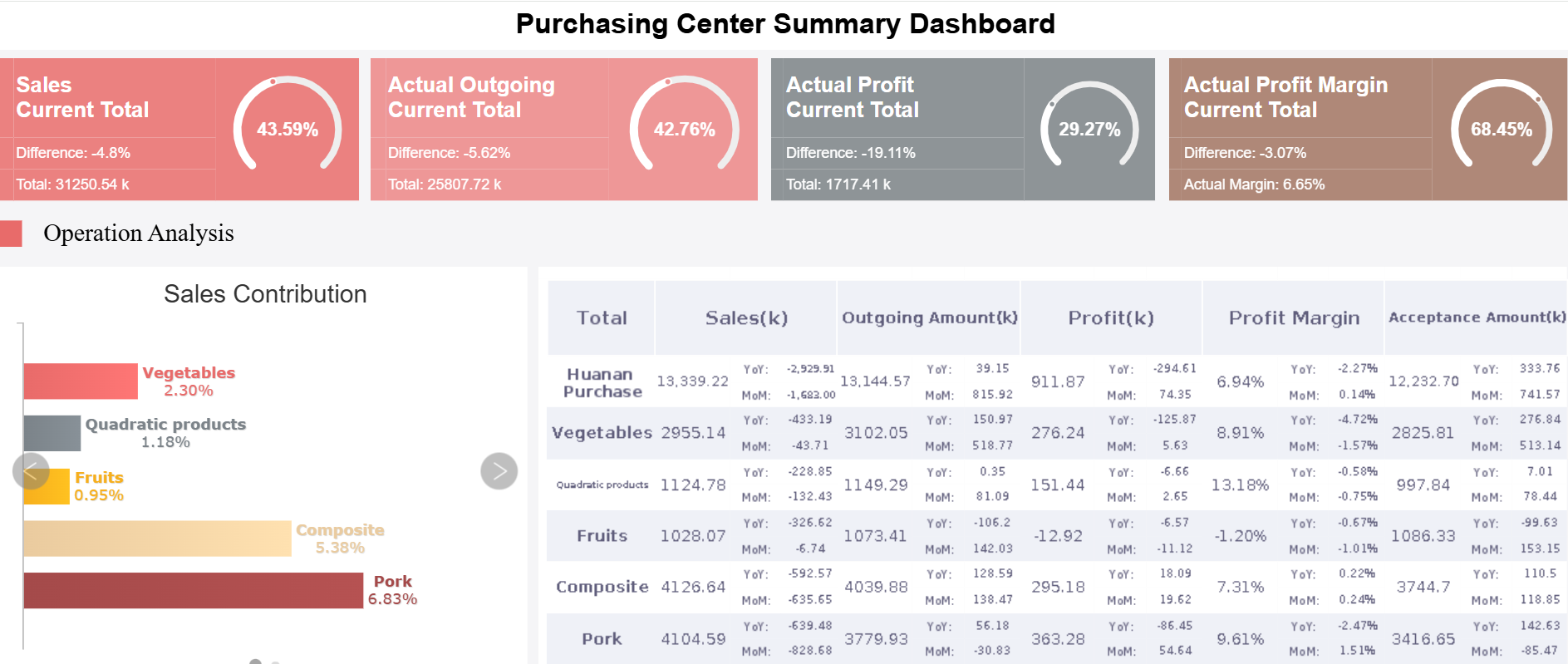

You can leverage FineReport to visualize supply chain performance, track key metrics, and compare different supply chain models. The platform supports data-driven decision-making, helping you optimize your supply chain strategy. FineReport enables you to monitor procurement, inventory, and sales in real time. You can identify bottlenecks, forecast demand, and respond to market changes faster.

In manufacturing supply chain management, FineReport provides a control tower that integrates procurement, inventory, and sales data. You can analyze supplier performance, manage contracts, and track inventory trends. FineReport supports real-world use cases, such as improving supplier negotiations, reducing inventory costs, and optimizing logistics operations. You can use dashboards and interactive reports to monitor business processes and make informed decisions.

When you focus on understanding the six supply chain model types, FineReport gives you the tools to select the best model for your business. You can adapt to market changes, improve efficiency, and achieve better outcomes by leveraging supply chain models and digital solutions.

Understanding and selecting the right supply chain model drives business success. You gain measurable benefits, such as cost efficiencies, cycle time improvements, and stronger engagement:

| Benefit Type | Description |

|---|---|

| Cost efficiencies | Streamlined processes can save 1%-2% on contracts and up to 25% on labor. |

| Cycle time improvements | Faster cycles improve working capital and reduce payables. |

| Enhanced service experience | Predictable processes improve partner and supplier interactions. |

You should regularly assess your supply chain strategy. Digital tools like FineReport help you create a command center, visualize data, and make timely decisions.

Data-driven decision-making improves supply chain management by increasing efficiency, accuracy, and strategic focus.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

What is Predictive Analytics in Supply Chain Management

Understanding Supply Chain Analysis and How It Works

What is Supply Chain Automation and How Does It Work

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025