Supply chain optimization means improving the flow of goods, information, and finances across your business network. In 2025, you face rising market demands and rapid changes in technology. You need to cut costs and boost efficiency to stay competitive. When you optimize your supply chain, you unlock several advantages:

Supply chain optimization means using strategies and tools to improve how goods, information, and finances move through your business network. You focus on making every part of your supply chain work together smoothly. This process helps you reduce waste, lower costs, and deliver products faster.

Modern supply chain optimization relies on several core components:

You use technology to connect systems and automate tasks. Inventory management ensures you have the right products at the right time. Demand forecasting helps you predict what customers will need. Strategic planning aligns your resources with your business goals.

Managing inventory is one of the most crucial aspects of supply chain optimization as it affects several other parts of your supply chain, including procurement, order fulfillment, and production planning.

Today, the Internet of Things (IoT) and advanced technologies have expanded supply chains. You now collaborate more closely with partners, distributors, and suppliers. This collaboration is essential for effective optimization. You also need to plan and forecast demand accurately, maintain the right amount of inventory, and reduce lead times and costs. These steps help you build a resilient and efficient supply chain.

Supply chain optimization matters more than ever in 2025. You face new challenges and opportunities shaped by technology, global events, and changing customer expectations. Recent Google search trends show a sharp rise in interest for supply chain management and analytics. This reflects your need to adapt quickly and stay competitive.

Key trends in supply chain optimization for 2025 include:

You also see manufacturers adapting to external pressures by diversifying sourcing and localizing production. Real-time data usage improves visibility and operational efficiency. Predictive analytics and strategic planning help you anticipate risks and manage disruptions.

Supply chain optimization gives you the tools to respond to these challenges. You can use automation and advanced supply chain optimization solutions to improve logistics, increase efficiency, and gain better supply chain visibility. By focusing on data and analytics, you make smarter decisions and build a more resilient business.

Demand forecasting stands as a foundation for supply chain optimization. You use forecasting to predict future customer needs and align your supply chain management strategy. There are two main approaches: qualitative and quantitative. Qualitative forecasting relies on expert judgment and market research. Quantitative forecasting uses historical data and statistical models to estimate demand. Many businesses combine both methods for a hybrid approach, which provides comprehensive insights.

| Method | Description |

|---|---|

| Delphi Method | A structured process involving expert opinions to refine forecasts through iterative feedback. |

| Collaborative Planning, Forecasting and Replenishment (CPFR) | Involves collaboration among supply chain partners to enhance forecast accuracy. |

| Simulation Models | Create virtual scenarios to assess the impact of various factors on demand. |

| Consumer Surveys and Market Research | Engages customers to gather insights on preferences and expectations. |

AI-powered tools have transformed demand forecasting in supply chain optimization. You can use predictive analytics techniques such as time series analysis, regression models, and neural networks. These models capture complex trends and respond to real-time signals. AI systems learn and adapt as new data becomes available. This agility helps you respond to unexpected events and rapid market changes, keeping your forecasts accurate and relevant.

Tip: Aligning supply and demand with AI-backed forecasting minimizes risk and boosts customer satisfaction.

Inventory management is a critical part of supply chain optimization. You must maintain the right stock levels to avoid shortages and excess inventory. Reviewing your inventory systems helps you streamline management. You can use continuous review or periodic review systems to track inventory. Quality control practices, such as checklists and standard operating procedures, ensure inventory meets customer expectations.

Automation plays a key role in inventory management. Automated systems improve inventory accuracy by 25-35%. You see a reduction in carrying costs by 20-30% and fewer stockout incidents by 35-45%. These improvements lead to better inventory turnover and higher supply chain efficiency.

| Metric | Improvement |

|---|---|

| Reduction in stockouts | 31% |

| Decrease in excess inventory | 22% |

| Improvement in inventory turnover | 19% |

Supplier and logistics optimization strengthens your supply chain management strategy. You need effective supplier relationship management systems to prevent disruptions. Building strategic partnerships with key suppliers leads to smoother operations and increased profitability. Supplier relationship management software streamlines processes and reduces risks.

Logistics optimization strategies enhance efficiency and reduce transportation costs. You allocate resources more effectively and plan deliveries using data-driven decision-making. This approach minimizes delays and improves overall performance. You gain better visibility into logistics operations, which supports faster delivery times and lower costs.

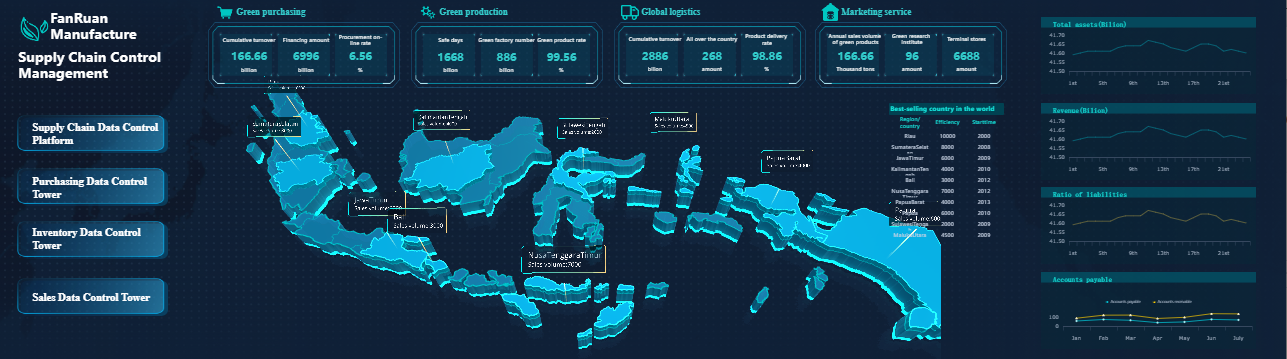

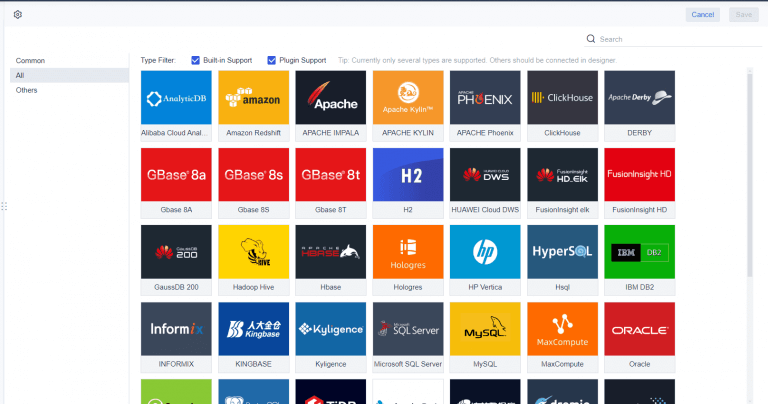

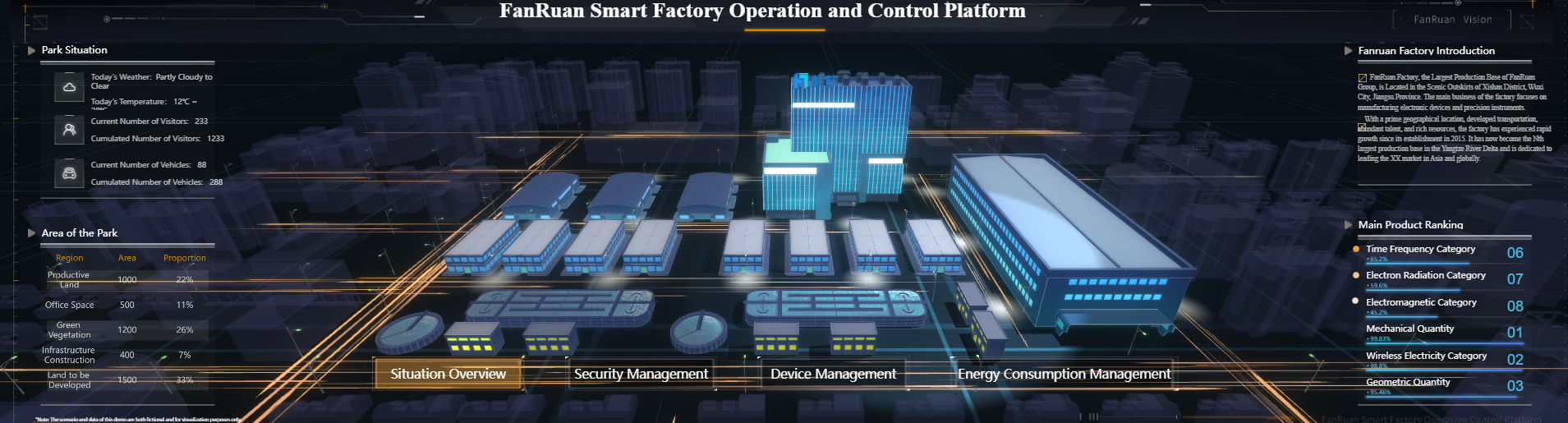

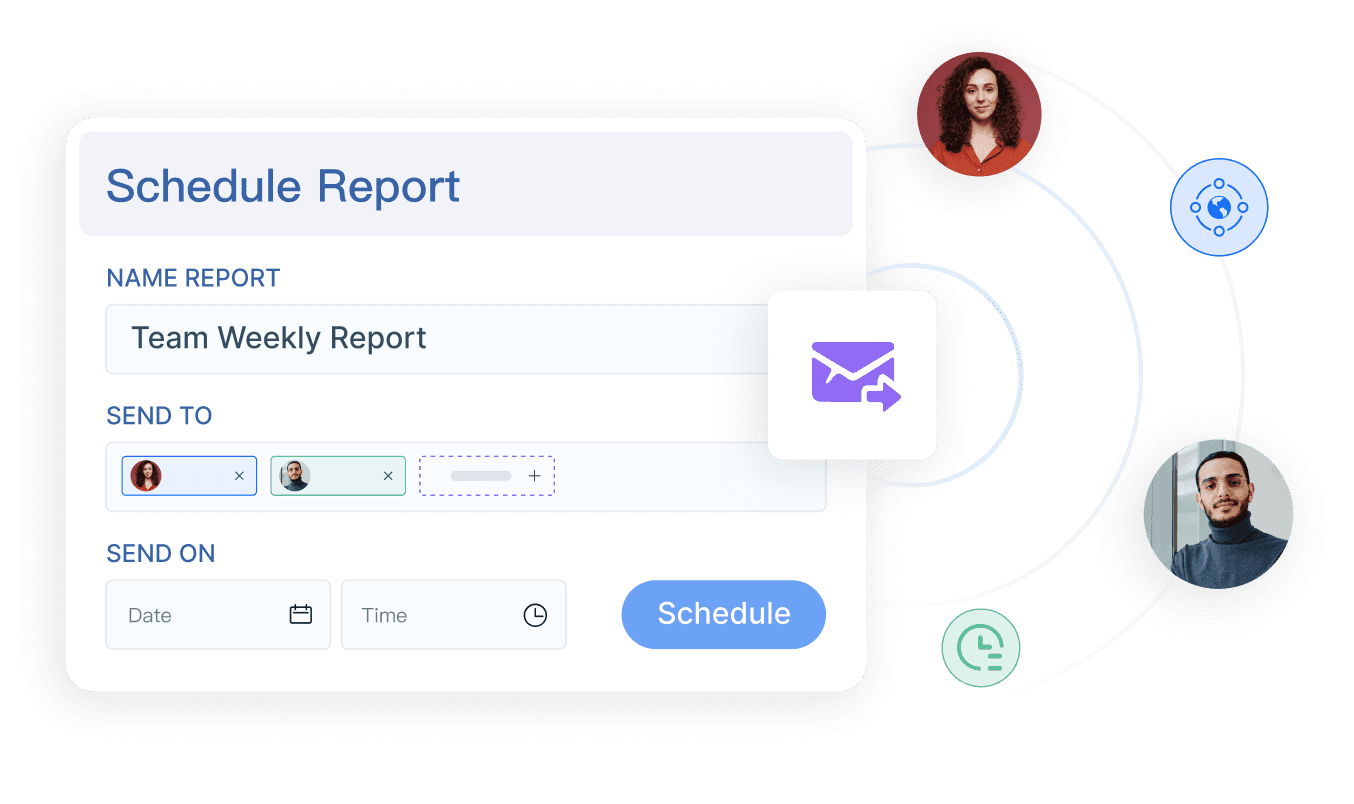

FineReport offers a powerful solution for supply chain optimization. You can connect, prepare, analyze, and visualize data from multiple sources. FineReport's workflow includes data integration, data processing, visual exploration, and secure publishing. You use over 60 connectors to unify data from databases, cloud warehouses, and APIs. This integration supports real-time analytics and improves supply chain management.

| Feature | Description |

|---|---|

| Data Management | Sort, filter, modify field names and types, delete columns, and reorder fields for better data management. |

| Collaboration Modes | Use Collaboration, Data Sharing, and Dashboard Sharing to facilitate teamwork and data sharing. |

| Subject-Based Analysis | Perform all analysis under subjects for easy collaboration and sharing. |

| Emergency Data Updates | Super admins can prioritize urgent data updates for timely access to critical information. |

| Intelligent Analysis | Multidimensional analysis identifies key factors affecting indicators, improving focus and efficiency. |

| Data Integration | FineReport integrates FineDataLink for flexible data processing and efficient data synchronization. |

You can create dashboards with drag-and-drop tools and apply real-time filters. FineReport supports multidimensional analysis, which helps you identify trends and key factors affecting supply chain performance. You collaborate with teams using subject-based analysis and dashboard sharing. Emergency data updates ensure you access critical information quickly. FineReport's intelligent analysis features allow you to focus on the most important metrics.

Manufacturing companies use FineReport to integrate procurement, inventory, and sales data. This approach improves supplier negotiations, reduces inventory holding costs, and enhances logistics performance. You gain comprehensive visibility and control over your supply chain. FineReport supports your effective supply chain strategy by enabling data-driven decisions and improving agility.

Note: FineReport empowers you to optimize supply chain management, boost efficiency, and respond quickly to market changes.

You can strengthen your supply chain optimization by focusing on visibility and control. Start by gathering critical documentation and using technology for data collection. Improve communication with direct suppliers to build transparency and accountability. Create resilience teams to assess vulnerabilities and implement mitigation measures. Invest in supply chain visibility software to gain a clear view of your logistics network. Identify and address blind spots, sometimes called supply chain "Bermuda Triangles," to prevent disruptions.

Key strategies include:

These steps help you maintain control and adapt quickly to changes, supporting an effective supply chain strategy.

Real-time data and analytics play a vital role in supply chain optimization. You can monitor supplier performance and spot inefficiencies as soon as they appear. Data analytics helps you avoid disruptions and minimize stockouts, which improves inventory management and supply chain efficiency. Centralizing information through analytics tools allows for better coordination and faster decision-making among stakeholders.

The measurable benefits of real-time analytics include:

By using predictive analytics and automation, you can react quickly to changes and address issues before they escalate.

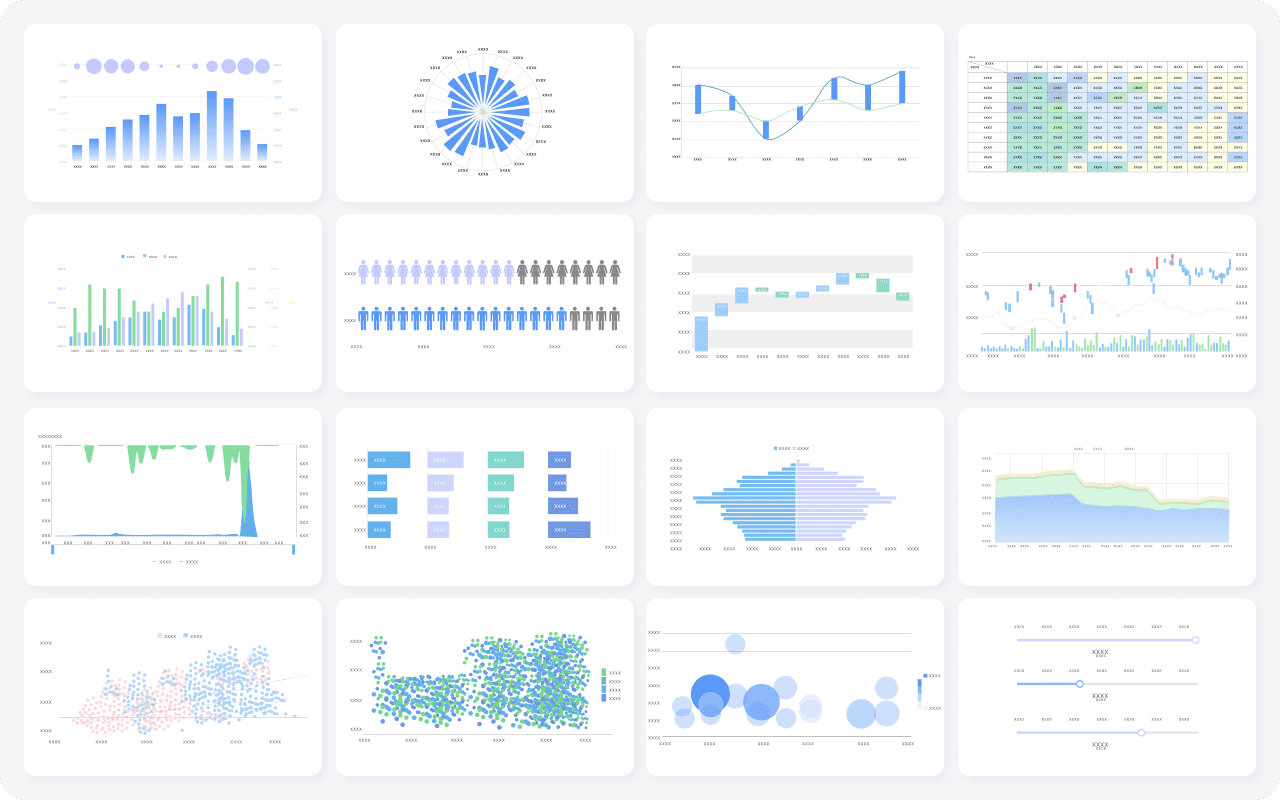

FineReport supports supply chain optimization by enabling real-time insights and decision-making. You can connect to multiple data sources and use collaborative dashboards to visualize trends and performance. FineReport offers over 50 built-in charts, making it easy to analyze logistics, inventory management, and supplier performance. You do not need SQL skills to manipulate data, which increases efficiency and supports informed decisions.

FineReport's solutions help you centralize data, automate reporting, and share insights across teams. This approach improves transparency and supports continuous improvement in supply chain management. By leveraging FineReport, you can implement an effective supply chain strategy, boost supply chain efficiency, and stay ahead of industry trends.

You gain several benefits when you focus on supply chain optimization. You see cost reduction through improved processes and better resource management. You increase efficiency and effectiveness across operations. Faster delivery and competitive pricing enhance customer satisfaction. You minimize waste and improve supply chain resilience. You unlock innovation and insights by using data analytics. Businesses report up to 15% lower costs after optimization. Inventory holdings can drop by nearly 50%. Advanced forecasting systems boost inventory accuracy rates to 95%, compared to 60% in traditional setups. AI systems can reduce forecasting errors by 50%. These improvements help you stay ahead of trends and strengthen your strategy.

Supply chain optimization empowers you to respond quickly to market changes and disruptions, ensuring consistent performance and growth.

You face several challenges in supply chain optimization. Accurate demand forecasting is critical for maintaining optimal inventory management. Rising transportation costs impact logistics and overall expenses. Unforeseen events can disrupt supply chains, causing delays and higher costs. Material scarcity and lack of visibility make it difficult to identify issues before they escalate. Increased freight prices add pressure to your budget.

| Challenge | Description |

|---|---|

| Demand Forecasting | Accurate forecasting is essential for optimal inventory management. |

| Rising Transportation Costs | Transportation costs form a significant part of supply chain expenses. |

| Supply Chain Disruptions | Unplanned events can cause delays and increase costs. |

You can overcome these barriers with proven solutions:

Manufacturing leaders demonstrate the impact of supply chain optimization through their strategies. Toyota uses Just-In-Time manufacturing to reduce inventory costs and improve efficiency. Coca-Cola optimizes its distribution network, lowering transportation costs and carbon emissions. Walmart relies on real-time inventory management to minimize excess inventory and optimize logistics. Apple maintains strict partner standards and audits, allowing agility and avoiding surplus inventory. These companies use data, analytics, and technology to drive improvement and maintain high performance.

You can learn from these examples and apply similar strategies to boost your supply chain resilience, efficiency, and transparency.

Supply chain optimization remains essential for your business success in 2025. You need to focus on sustainability, resilience, and supply chain transparency to meet new challenges. Many companies now use artificial intelligence and machine learning to improve forecasting and operations. To boost supply chain resilience, diversify suppliers, use flexible transportation, and adopt integrated solutions like FineReport for real-time data access. Regularly review your processes and empower your team through training. Assess your supply chain today and commit to best practices for greater efficiency and agility.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

What is Predictive Analytics in Supply Chain Management

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025